Once these details have been looked at in detail, the impact could be significant, especially considering the size of the energy and IT industries. It also has the potential to be used in the thermal management of highly integrated electronics.īut to apply our method to such applications, more details need to be addressed, e.g., scalable texturing technique, optimization for different types of fluid (we tested with water while dielectric fluids are required for electronics), and optimizing a surface for high pressure condition (which is typical for power plant boilers). IE: What environmental impact could this have?Įnhanced boiling could save a significant amount of energy for electricity generation in power plants. So now, the first step when looking to apply our method to a domestic or industrial level application will be to find a scalable way of creating a similar surface textures, so our method could more easily be scaled up to practical dimensions. These kinds of surfaces, however, were fabricated by clean-room processes (silicon wafer-based processes) and experimental tests were done at laboratory scale. In this work, we demonstrated the strategy to enhance boiling by surface engineering. IE: Could this make a difference on a domestic or even industrial scale? In general, the efficiency and maximum capacity have a trade-off whereas here, we achieved a way of significantly enhancing both of them by engineering surface structures in a multiple dimensions from nanometer to millimeter.

critical heat flux or CHF) of boiling heat transfer. The engineered surface can improve the efficiency and maximum capacity (a.k.a. But by separating those cavities by two millimeters, we separate the bubbles and minimize the coalescence of bubbles. Those micro cavities define the position where bubbles come up. The microcavities were then positioned at the ideal length to optimize the process. This effectively keeps the bubbles pinned to the dents and prevents them from spreading out into a heat-resisting film.

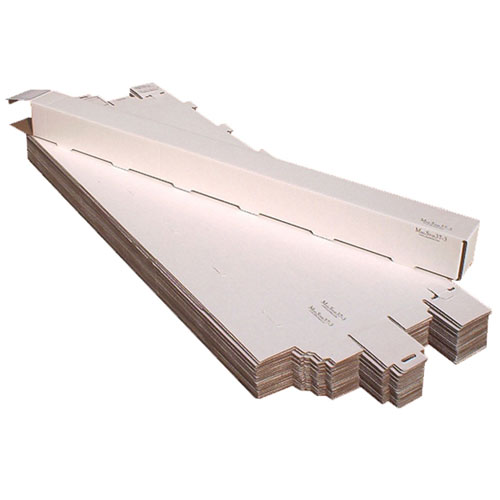

Blueprint storage series#

If we have vapor in between the surface and water, that prevents the heat transfer efficiency and lowers the CHF value.īy adding a series of microscale cavities (dents) to a surface, we were able to control the way bubbles form on that surface. That film introduces resistance to the heat transfer from the hot surface to the water. If we have lots of bubbles on the boiling surface, that means boiling is very efficient, but if we have too many bubbles on the surface, they can coalesce together, which can form a vapor film over the boiling surface. This is quite a development as there’s generally a tradeoff between the two, so anything that improves one of these parameters tends to make the other worse.īoth parameters are important, but enhancing both parameters together is kind of tricky because they have an intrinsic trade-off. Youngsup Song: The team were able to improve the two key parameters that are conducive to the boiling process, the heat transfer coefficient (HTC) and the critical heat flux (CHF). Interesting Engineering: Talk us through how this happened Youngsup’s words have been edited for brevity and clarity.

0 kommentar(er)

0 kommentar(er)